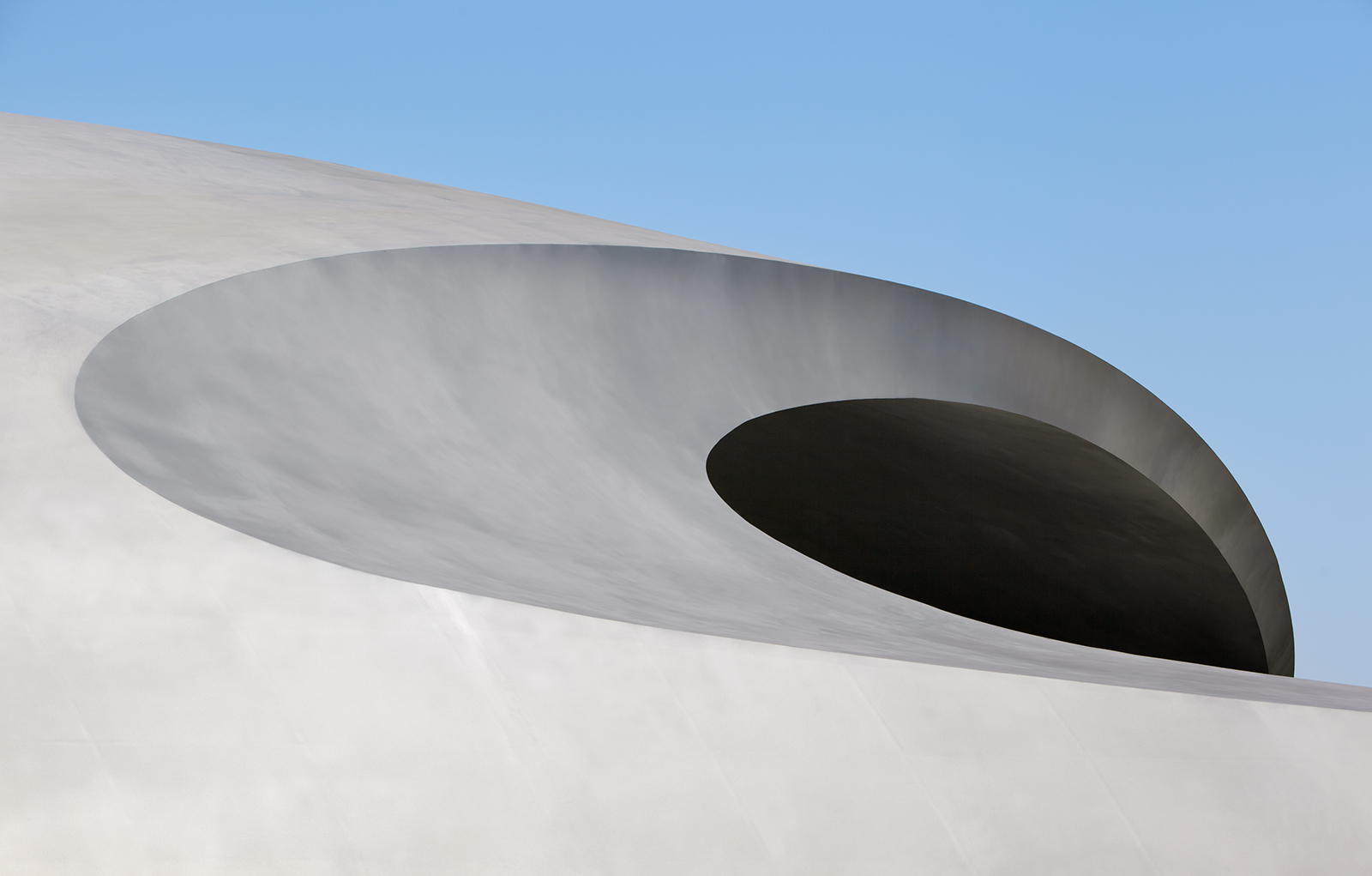

Porsche Pavilion, Wolfsburg, Germany

The swooping lines of a Porsche have long been considered a triumph of automotive design, but what if an architect were given the chance to create an homage to those classic sportscars?

The Porsche Pavilion in Germany is just this – a powerful showcase of the architectural possibilities offered by steel. Its unique plunging roof forms a steel-clad edifice hanging over a pool of water like a vehicle frozen in motion.

Project team:

- Architect: HENN

- Design Team: Martin Henn, Klaus Ransmayr Paul Langley

- Structural engineers: Schlaich Bergermann und Partner

- Infrastructure design: Niermann Consult

- Structural steel: Zentraal Staal

- Envelope Contractor: Centraalstaal B.V., Groningen

- Client: Dr. Ing. h.c. F. Porsche AG / Autostadt GmbH

Design heritage

Blurring the lines between sculpture and architecture, The Pavilion represents the merging of Porsche and the Volkswagen Group. When Volkswagen rebought the car brand in 2012, the decision was made to erect a building that reflected its design heritage right in the heart of the VW’s Autostadt, a VW-themed park that attracts two million visitors a year. German architecture firm Henn was chosen to design it.

Zentraal Staal sourced the steel from more than 30 locations, and a shipyard in Stralsund was tasked with prefabricating 620 sheets of stainless-steel cladding with welded ribs.

“Porsche is literally the nucleus of the Volkswagen Corporation,” says Klaus Ransmayr, head of Henn’s Berlin studio. He points out that the two companies share part of their history, as Ferdinand Porsche designed the very first Volkswagen car, a VW Beetle. In fact, the two iconic cars share an uncanny resemblance. “So the central location of the pavilion reflects this historical connection and the importance of the brand for VW,” Ransmayr adds.

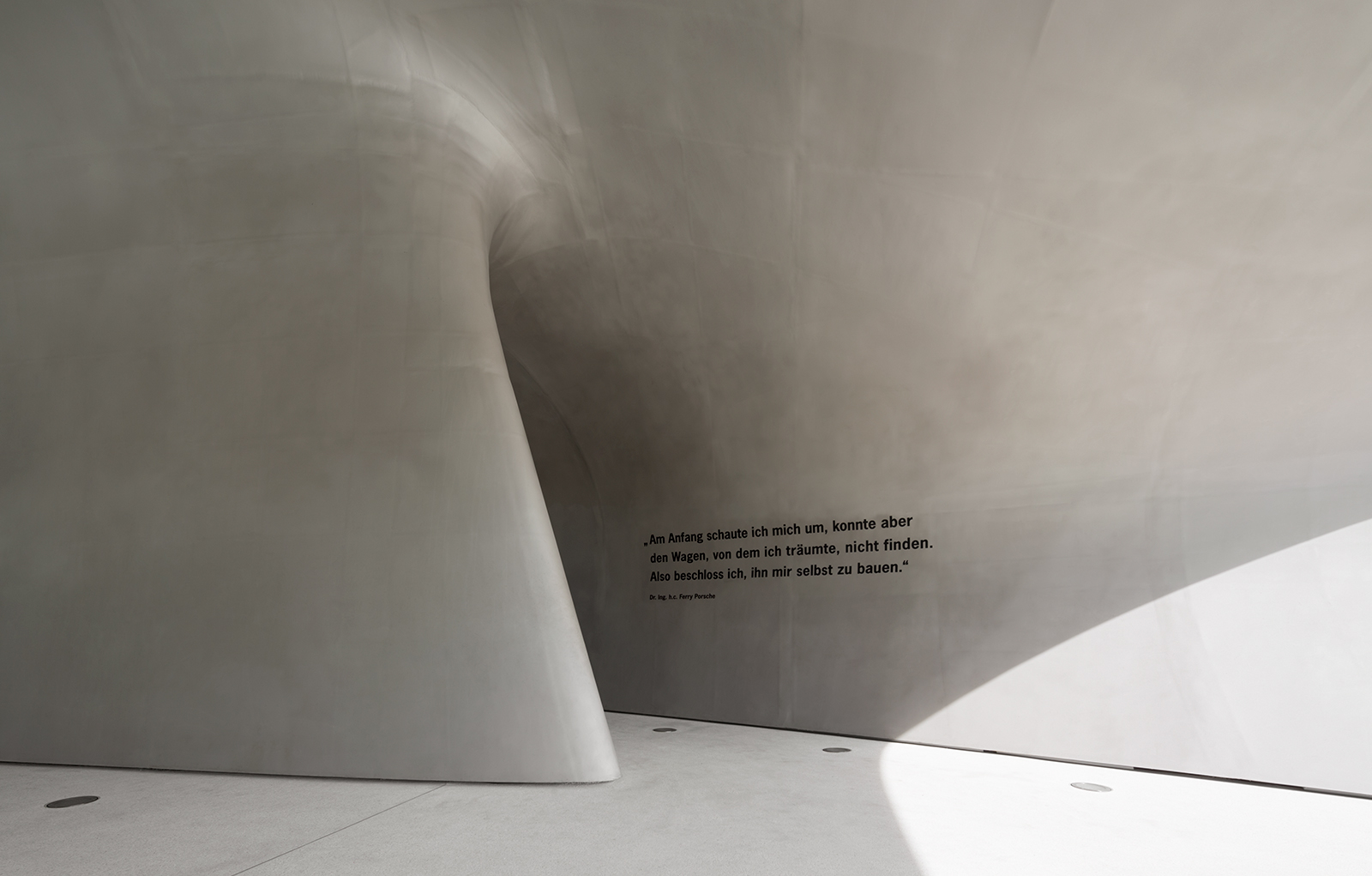

Henn was commissioned to design a building that epitomised the brand’s distinctive aesthetic. “As with every other brand pavilion in Autostadt, the idea is to transport a feeling of the brand’s characteristics without showing a car,” says Ransmayr. “For Porsche, the ergonomic form and silhouette is one of the most significant elements, its USP.”

The swooping lines of the roof perfectly mimic Porsche's timeless aesthetic

The building employs monocoque technology, where the body and chassis are integrated

Precise GPS measurements ensured the correct placement of each roof segment

Monocoque steel building

Henn’s solution was a novel approach – a highly innovative seamless building skin constructed from stainless steel. In this futuristically organic form with dynamic lines, the roof, external walls and internal spaces merge into one continuous single form. Its curved asymmetrical steel roof acts as a cantilever 25m over an adjacent pool, sheltering two entrances. The roof creates outdoor seating space for an audience of a few hundred visitors, where lectures, readings and concerts take place, along with presentations of new cars.

Inside, there is 400m2 of space for presentations and exhibitions in the basement. Down here, 25 silver vehicle models are on show, including the original Porsche – a 356 No.1 built in 1948.

As well as borrowing its aesthetic language from Porsche, the building shares some of the brand’s construction techniques. Both the automotive and aerospace industries employ monocoque technology, meaning the chassis is integral with the body.

Porsche Pavilion:

- Construction period: Aug 2011 to May 2012

- Floor area: 1,400 m2

- Monocoque: 2,550 m2

- Weight: 425 tonnes

- Material: Stainless steel plate 10-30 mm

In the exhibition space, 25 silver vehicle models are on show, including the original Porsche – a 356 No.1 built in 1948.

In the exhibition space, 25 silver vehicle models are on show, including the original Porsche – a 356 No.1 built in 1948.

A construction marvel

With the ambitious design already representing a substantial architectural and engineering challenge, the erection schedule and site conditions also presented a set of significant complications.

Construction time was limited to night-time – from 7pm to 6am – since the site had to be open to visitors during the day. This, combined with the extremely short timeframe of only 10 months, meant that the process had to run as efficiently as possible.

Here, prefabricated, double curved steel plates were produced over a period of four months. More than 2,550m2 of surface was hand formed, with quality control ensured by 3D measuring techniques to ensure that tolerance requirements were met. This exacting process also ensured that no production errors would impact on the schedule when it came time to assemble the pieces.

The spot welding required extreme precision and GPS measurements were used to ensure the correct placement of each piece of the structure, again cutting down on potential site complications.

An enduring steel finish

The curved roof of the Porsche Pavilion not only forms a spatial enclosure, it also doubles as a load-bearing structure. Stainless steel was chosen for the structure because, as well as being strong enough for the task, it looks sensational, reflecting the changing colour of the seasons.

Zentraal Staal sourced the steel from more than 30 locations, and a shipyard in Stralsund was tasked with prefabricating 620 sheets of stainless-steel cladding with welded ribs. Usually panels of this type would need to be coated, but instead Henn opted to blast the surface with a stainless-steel grain. “This process maintains the purity and honesty of the material, while also producing a frosted surface that works without any additional corrosion prevention,” explains Ransmayr.

“The high quality of the material and the superb workmanship of welding the unique pieces together make it very durable against the environment,” says Ransmayr. “The Porsche Pavilion will remain a tourist magnet and an icon for the brand for many years to come.”

Images: HG Esch